Customized Injection Nozzles for Autoclave and Severe Service Needs

Injection tubes, oxygen sparge tubes, and dip tubes are exposed to substantial erosion in pressurized, heated, slurry mixing tanks. The presence of acid and elevated temperatures also requires that injection nozzles be corrosion resistant. Titanium is a preferred material in corrosive environments, but is susceptible to auto-ignition in oxygenated environments. Caldera's dual wall injection nozzle designs minimize this hazard.

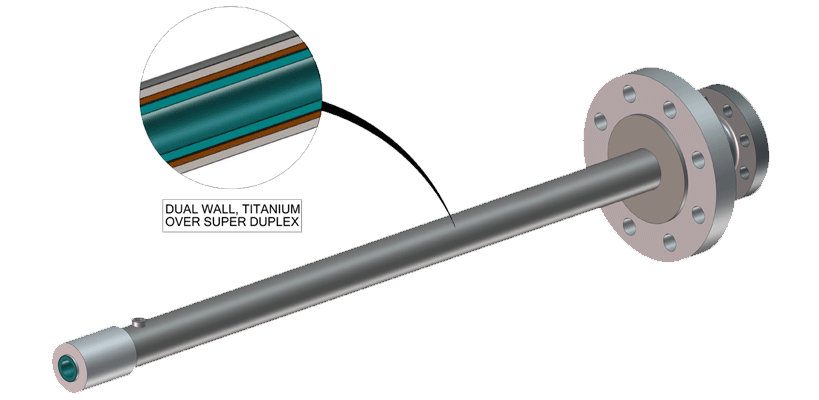

Advanced Injection Tube Designs for Increased Life

There are numerous design formats for injection nozzles, and Caldera can work with you to determine the best fit for your injection needs.

Single wall injection tubes are alloy tubes that offer reasonable life in some applications.

Dual wall injection tubes generally have an outer titanium, acid-resistant layer, and an inner alloy layer that can safely handle oxygen. Where oxygen fires are a concern and acid is also present these dual wall injection tubes can offer considerably longer service life.

Transitioning injection tubes utilize a single wall super duplex stainless steel in the vapor space which then transitions to a dual wall tube at the fluid level. This design provides the advantage of the titanium’s resistance to corrosive wear in the fluid, but the safety of super duplex in an oxygen enriched environment.

Ceramic Injection Nozzles for Longer Service Life

Injection tubes will often erode at the nozzle exit due to flow turbulence. This is dangerous because it can expose titanium to injected oxygen and pose a fire hazard. To protect against fire hazard and extend the life of the nozzle exit Caldera offers ceramic lined injection nozzles.

Please call us at +1 801-356-2862 with any inquiries about Caldera injection nozzles.

Email us and one of our engineers will review your questions and concerns and get back to you within 24-hours. Contact us here.