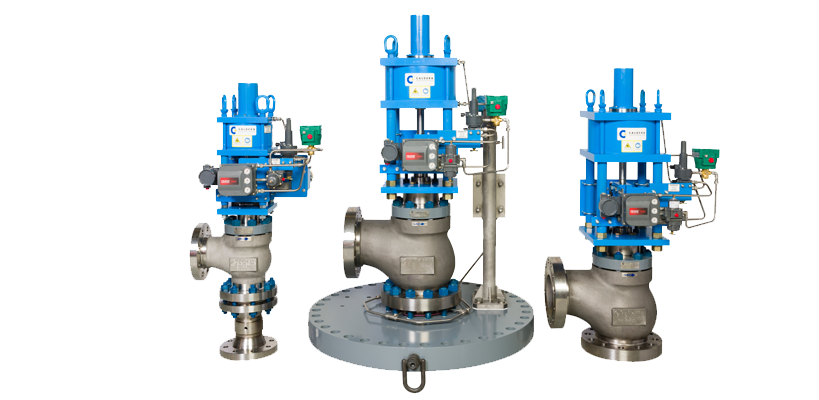

Ceramic-trimmed Severe Service Valves

Using ceramic trim in valves helps extend the service life of your equipment. Where other materials fail, ceramic-lined parts are better suited to withstand abrasive and corrosive slurries, and other severe service environments. Caldera’s ceramic-trimmed components help mitigate these destructive conditions to extend service life.

Ceramic Solutions

In order to maximize the service life of ceramic-lined components it is critical that Caldera understand a customer's process conditions. Once we understand the process conditions we then engineer the equipment and design the ceramic-lined parts and pressure letdown components.

Engineered systems with ceramic-trimmed valves provide superior erosion protection. Caldera offers more than ceramic-lined equipment; we offer ceramic-lined solutions.

Ceramic-lined Components - An Investment

When critical components fail production comes to a halt. Ceramic-trimmed valves can dramatically reduce the frequency of failure from erosion in severe service applications. While the cost of incorporating ceramics can be substantial, it is minor compared to the cost of lost production. Specifying ceramic-trimmed valves is an investment in your operations.

To learn more how Caldera ceramic-trimmed valves can extend the service life of your equipment call us at +1 801-356-2862.

Email us and one of our engineers will review your questions and concerns and get back to you within 24 hours. Contact us here.