Engineering and Manufacturing

Engineering & Manufacturing

Model Validation

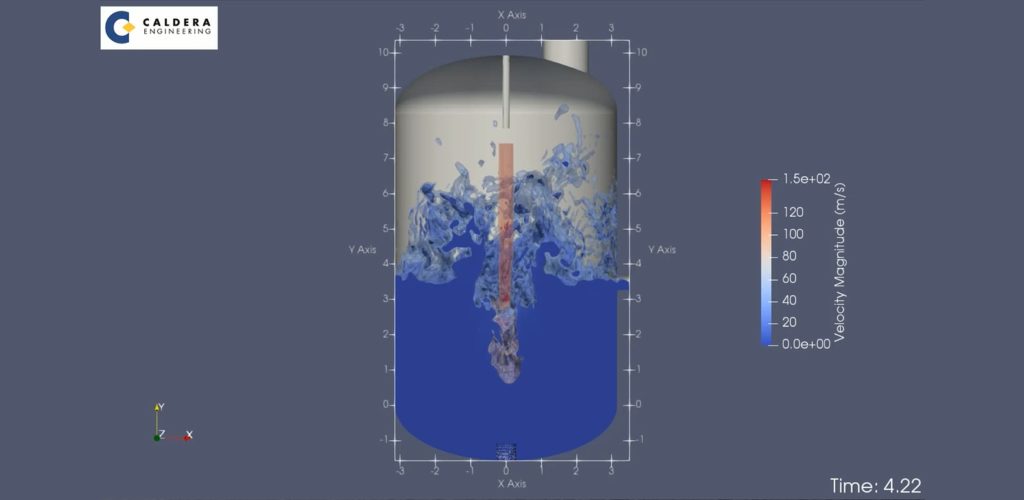

Caldera develops and uses analytical models to predict the behaviors of supersonic flashing flow. Caldera then designs equipment to effectively control and dissipate the energy associated with this flow.

In order to best serve customers, Caldera conducts tests and experiments to verify the analytical models. Verifying and adjusting the models allows Caldera to continually improve our severe service solutions.

To verify these analytical models, Caldera has:

- Installed wear plates at customer sites to verify energy dissipation plume shape1

- Built a lab scale autoclave letdown system to validate plume shape

- Built a gas/liquid mixture letdown system to further understand blast tube energy dissipation2

- Checked customer impingement block erosion against pool penetration model3,4

Model Validation Approaches

Caldera actively plans and carries out model validation. Also, as opportunities arise, we check our models against unexpected customer upset conditions.

1) Wear plates used to verify if erosion from flashing flows matches model predictions

2) Lab scale blast tube to check plume shape

3) Pool penetration model

4) Worn impingement blocks from bottom of flash vessels