Caldera Products

Caldera Products

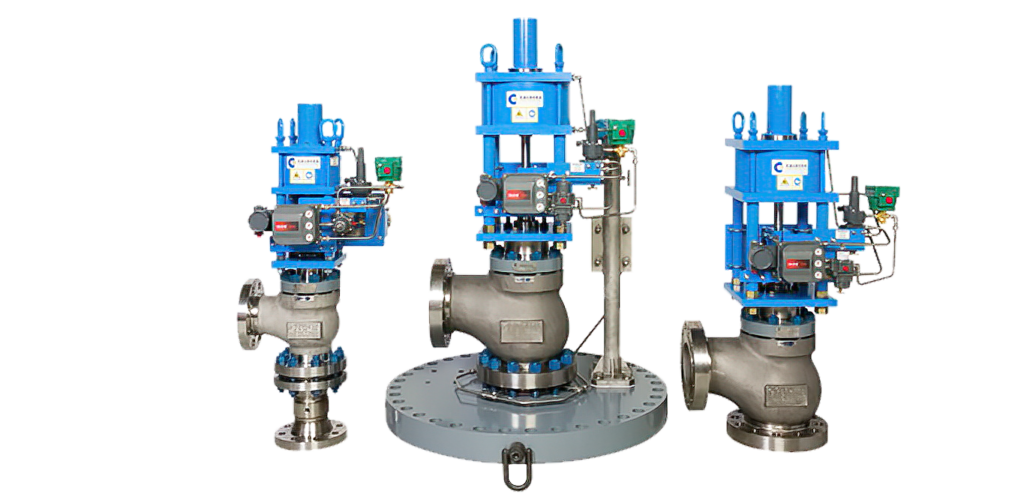

Ceramic-trimmed Severe Service Valves

Using ceramic trimmed valves in erosive and corrosive environments can help extend the service life of equipment. Where other materials fail, ceramic-lined parts are better suited to withstand abrasive and corrosive slurries, and other severe service environments. Caldera’s ceramic-trimmed valves help mitigate these destructive conditions to extend service life.

Valve Sizes

Caldera’s engineering and manufacturing capability allows us to serve a wide range of customer situations, from starting new operations to expanding capacity at existing plants. Caldera regularly manufactures slurry letdown valves with nominal sizes ranging from 1”-18” (DN 25-450). Larger valves can reasonably be manufactured. If you need something larger, please let us know.

Pressure Class Ratings

Caldera typically engineers and manufactures valves to AMSE class ratings 150-900 (DIN PN 20-150). Other valve class ratings can reasonably be manufactured. If you need something outside this range, please let us know.

Ceramic Solutions

To maximize the service life of ceramic-lined components it is critical that Caldera understand a customer’s process conditions. Once we understand the process conditions, we engineer the equipment and design the ceramic parts.

Engineered systems with ceramic-trimmed valves provide superior erosion protection.

Ceramic-lined Components – An Investment

When critical components fail, production comes to a halt. Ceramic-trimmed valves can dramatically reduce the frequency of failure from erosion in severe service applications. While the cost of incorporating ceramics can be substantial, it is minor compared to the cost of lost production. The higher cost of incorporating ceramics is quickly offset by increased plant uptime.