Caldera Products

Caldera Products

Oxygen Isolation Valves

High purity gaseous oxygen injection is a vital part of any Pressure Oxidation (POX) autoclave circuit. Ball valves are commonly used as isolation valves between the oxygen supply and the harsh environment inside the autoclave. Caldera oxygen isolation valves are designed to provide significant advantages to customers.

Pure oxygen environments significantly increase the risk of metallic fires. Selecting the appropriate materials and valve design is essential to minimize this hazard.

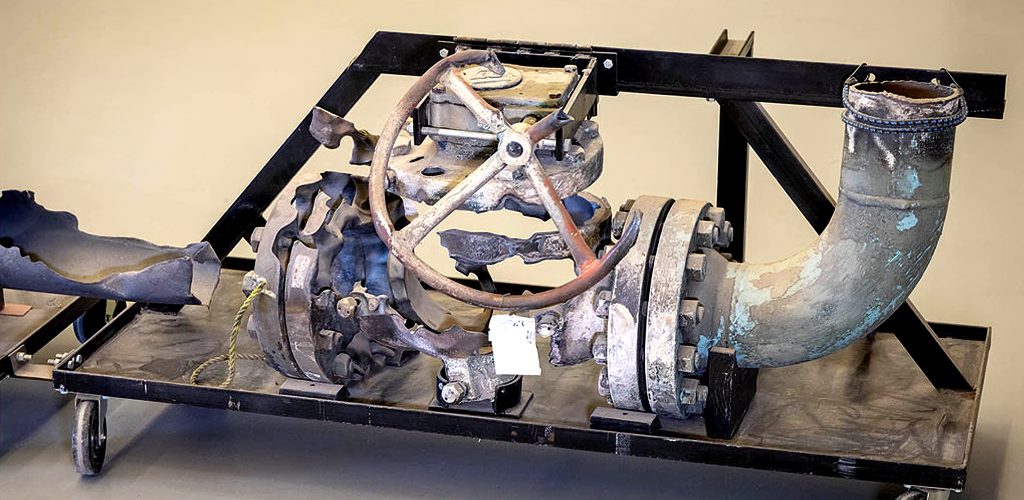

Example of valve consumed in oxygen-induced fire (not a Caldera valve)

Caldera oxygen isolation valves are typically constructed from forged rather than cast materials, ensuring lower porosity and improved performance in gas applications requiring precision cleaning.

Solid sintered silicon carbide, rather than a coating, is used for sealing surfaces. This material is non-sparking, non-reactive, and highly corrosion-resistant, making it ideal for the autoclave environment. Using durable, fireproof materials in contact with oxygen reduces fire risk and extends valve life.

The angle-type Caldera valve operates similarly to a globe valve, aligning with CGA G-4.4 recommendations for throttling. Ball valves are fast acting valves and are therefore limited to no differential pressure when cycling, which is not always possible in emergency situations. The Caldera design allows safe cycling under differential pressure and in emergency shutoff scenarios. The flow area between the plug and seat which is subject to the highest flow velocity and ignition risk, is fully constructed from fireproof ceramic.

Advantages over other isolation valves includes:

Linear Motion – Plug opening eliminates scraping of metallic surfaces like the rotary ball and seat. This preserves the sealing surface. The “flow-over” design ensures that the plug is always exposed to clean oxygen when open. Gland seals are located in the clean side of the valve. Any slurry that settles inside the sparger will not increase the torque requirement to open the valve.

Lower Initial Velocity – Compared to ball valves, the Caldera valve’s large initial flow opening and linear design prevent high-velocity flow over metallic parts during cycling with a differential pressure. This reduces the risk of metallic fire ignition.

Material Selection – Caldera oxygen valves are NOT made from any reactive metal or have any reactive metal components. The metallic parts of the valves are made from super duplex stainless steels or high nickel alloys like Alloy 20 or Inconel 625. No metallic parts are subjected to high velocity oxygen nor are in locations where impingement is likely. All metallic components are thicker than the 3.18 mm to 6.35 mm as specified in CGA G-4.4 Appendix D. Metallic materials of construction (MOC) are dependent on customer preference and corrosive properties of the duty. The sealing surfaces and the extended seat that can experience impingement are all made from fired ceramics that are considered as inflammable according to ASTM G63. All “soft” goods like stem packing are located outside the flow path and made from CGA G-4.4 and ASTM G63 recommended materials.

Reduced Inventory & Cost of Ownership – Servicing Caldera valves is straightforward, requiring only plug and seat replacement. This can be done on-site. The ability to service the valves on site greatly reduces the requirements of operational spares. Service kits typically cost less than 30% of the total valve price, reducing the need for spare valves and lowering long-term ownership costs.

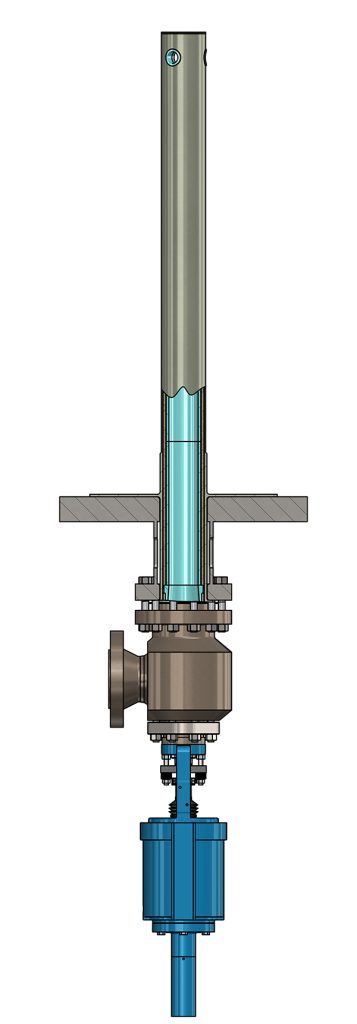

Complete System – The Caldera Oxygen Isolation Valve is designed for seamless integration with the Caldera Ceramic-Lined Oxygen Sparger. This pairing ensures proper connection, reduces oxygen flow interruptions, and minimizes the exposure of metal components to high-velocity oxygen. The result is improved system reliability, less plugging, and longer service life.

Contaminants such as hydrocarbons and metal particles can act as fuel in oxygen-rich environments. All Caldera oxygen duty valves are cleaned to ASTM G93 standards, with options to comply with EIGA and CGA G-4.1 standards, ensuring minimal risk of contamination.

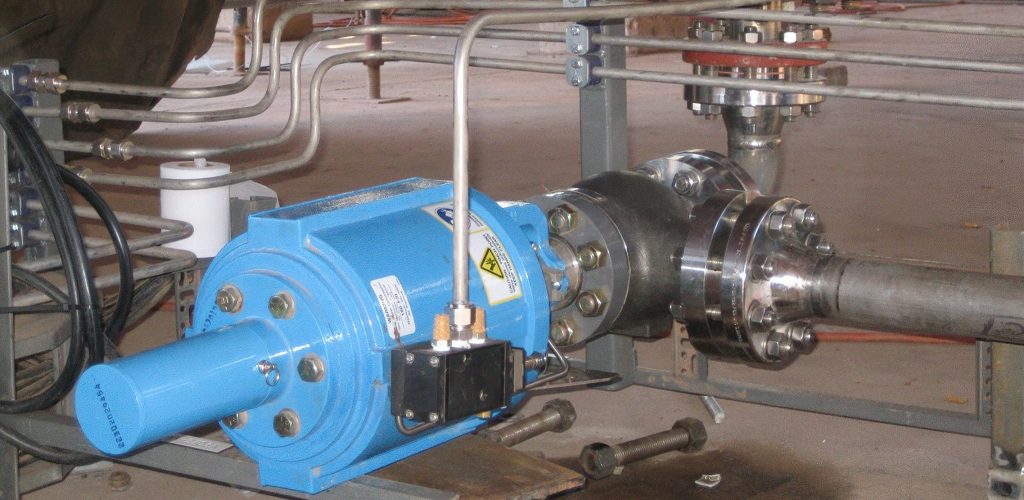

Oxygen Isolation Valve and Sparger Assembly