Caldera Products

Caldera Products

Ram-Style Valves

Injecting water into autoclave discharge lines slightly lowers slurry temperature, which in turn reduces saturation pressure. This effectively increases the overpressure across the letdown system, thereby improving its flow potential for a given choke or trim size. This technique has been successfully employed to expand the operating range of letdown systems.

A key operational benefit of this practice is that when water injection is stopped, the letdown valves can function at a higher stroke position, even at reduced flows. Operating valves in a more open position improves valve trim life due to better thermal profiles across the plug and reduced accumulation of solids between the plug and seat.

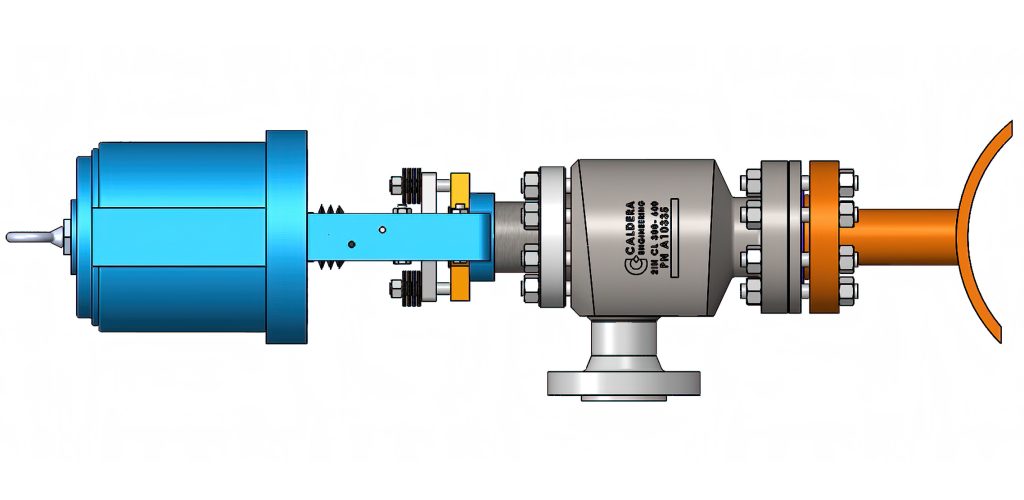

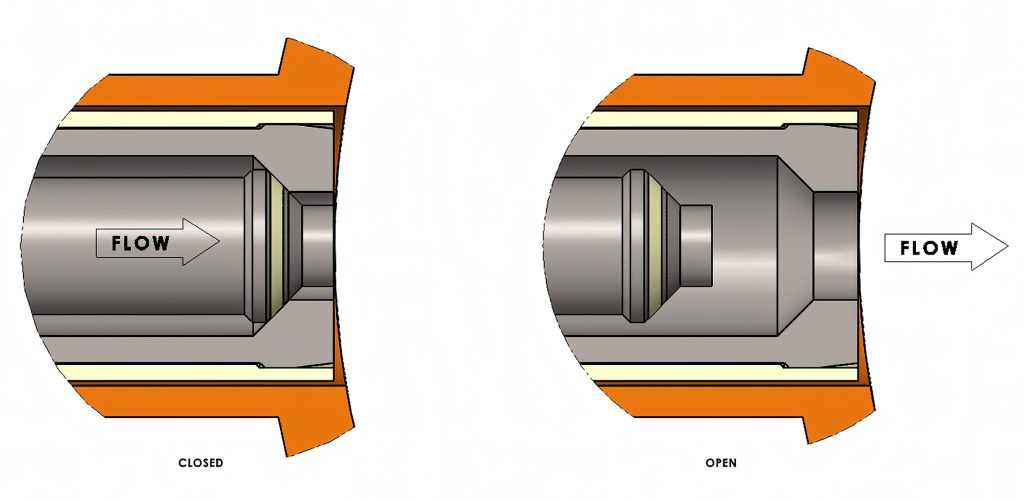

However, in slurry and particularly scaling applications, the intermittent operation of water injection and drain valves can lead to blockages. To mitigate this, the industry often uses RAM-type valves. These valves feature a “piston” or ram that occupies the stagnant leg of the piping Tee when injection or drainage is not required. The piston retracts when flow through the Tee is needed, effectively preventing scaling and blockages. While the concept is sound and widely adopted, conventional RAM valves have some limitations, particularly around sealing performance.

To address these challenges, Caldera developed a specialized RAM-type valve for critical water injection and drainage applications. The Caldera design overcomes some of the typical issues seen with standard RAM valves, such as poor sealing that necessitates secondary isolation valves to prevent slurry ingress or leakage. Caldera valves feature a piston-style plug that seals directly at the tip, mating against a seat formed by a protective sleeve within the Tee. In high-wear applications, ceramic components can be used to drastically reduce wear. A major benefit is that using a plug and seat concept allows for the valves to be used as modulating valves to control the water flow at the entrance of the main line. The piping remains clear and unblocked, while the flow is controlled at the injection point, eliminating the need for a separate modulating valve and reducing the need for isolation valves upstream.

Since the first installation over a decade ago, Caldera Water Injection Valves have consistently demonstrated robust and dependable performance with a low total cost of ownership.